Do you feel like you are wasting precious time on extended forklift travel lengths in your warehouse/application? Time is money so stop wasting it! Below are a few tips that you can utilize to cut forklift travel times furthermore result in greater efficiency and saving you money.

1st Recognize some Challenges:

- Frequently handled product is separated due to size or storage handling requirements

- Stock-Keeping Units or SKU’s has increased to increased demand for products

- New product lines are being stored wherever there is room

- Aisles are congested with people, equipment, and product

- Floor conditions are poor forcing operators to slow down

- Your fleet is small and may require more trips

- Warehouse layout may cause inefficient workflows

Once you recognize some of the challenges, let’s look at the factors that can reduce forklift travel time:

Warehouse layout design:

If you were to draw an arrow reflecting the path of which product flows in your operation. Maintaining a single-direction flow from receiving to shipping to optimize travel time.

If the arrows you draw go in different directions, double back, or go opposite to the desired location, there are your problem areas.

- Try to minimize travel distances between pick up and drop off areas.

- Reduce the amount of forklift and other congestion in high-travel locations.

- Improve the access to product areas.

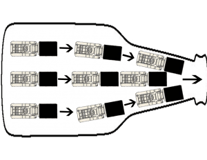

- Reduce bottlenecking ( See Image Right ).

Do you know what cross-docking is:

- Cross-docking is the process when product from a manufacturer or supplier are distributed directly to the customer or retail outlet with minimal handling and storage time (Fast moving inventory).

- Identify the products that can benefit from cross-docking. Usually, the best products are bar coded with high inventory carrying costs and easy to predict demand.

- Move your cross-docked inventory from inbound delivery, directly to outbound shipping.

Consider the space you have:

- Investigate different types of racks for high volume SKU’s.

- Consider vertical or narrow aisle strategy for better use of space.

Strategically position products:

- Place your high traffic products close to their destinations.

- Store fast-moving or heavy products close to ground level for minimized retrieval time.

- Determine inventory trends based off of seasonal movement, and adjust based on traffic.

For more information or tips on reducing your fleets travel time, contact us at 330-633-6000 and we will be more than happy to provide solutions.